SME conditions stable but still below average

Insight

If you eat meat and live in Australia you’ve most likely eaten the award-winning fare created by Bertocchi Smallgoods, the nation’s largest continental smallgoods manufacturer.

If you eat meat and live in Australia you’ve most likely eaten the award-winning fare created by Bertocchi Smallgoods, the nation’s largest continental smallgoods manufacturer.

The founder of Bertocchi Smallgoods, Modesto Bertocchi, came to Australia from Sassalbo, Tuscany in 1948, sailing from Genoa with just one suitcase and a vision to create a successful life in his new homeland. He met his wife Ursula, the daughter of German Jews who’d fled Europe before the Holocaust, at a Melbourne dancehall.

Though such cross-cultural pairings were unusual at the time, the couple thrived, setting up a café in Lygon Street, Carlton just before the 1956 Melbourne Olympic Games and installing a black-and-white television to encourage customers to come in and watch all the sporting action. Catering to everyone from early morning coffee buyers to evening diners, the café provided the foundation that allowed Modesto, a butcher by trade, to establish what grew to be a network of 60 butcher shops across Melbourne.

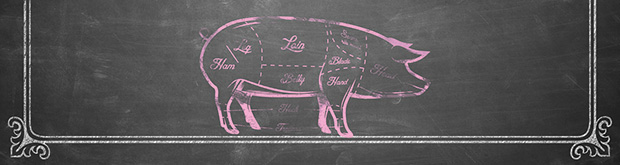

After recognising there was a growing appetite for quality European smallgoods in Australia, Modesto purchased 12 acres of land in Thomastown, north of Melbourne, and launched Bertocchi Smallgoods in 1972. Four decades on, the site has expanded to 100 acres, housing 12 manufacturing plants and a distribution centre. The company also operates a national network of distribution centres and a large fleet of trucks that ferry vast amounts of ham, bacon, salami, mortadella, prosciutto, pancetta and frankfurts to delis and supermarkets across the nation, where the red-and-green Bertocchi logo is now omnipresent.

Like his brother Andrew, John Bertocchi was brought up in the family business. “My parents ensured that Andrew and I got a good education at Xavier College but neither of us were academically inclined, so it was a natural progression to join the family business after finishing high school. Sadly, dad passed away from prostate cancer in 2002 at which point we had to work out what to do with the business. We opted to move to a corporate structure that would set our business up to compete well into the future; Andrew and I became executive chairmen and hired a CEO to handle the day-to-day management.”

The current Chief Executive Officer, Peter Paolino, has been with the business for the past nine years and the company remains a 100 percent family-owned Australian business. The structure they put in place has enabled Bertocchi Smallgoods to expand into new platforms.

While second-generation sibling rivalry has derailed many a successful family business, John says it’s never been an issue. “My brother and I are loyal to each other and we respect each other,” he says. “That’s probably the main criteria to our success, the fact that we are so loyal and passionate about our business and our relationship.”

Recently, the company welcomed the first of the third generation, with John’s son Stephen joining the marketing team. The family atmosphere also extends to the company’s employees, who can number up to 600 during peak production periods.

In less capable hands, Bertocchi Smallgoods could easily have joined the long list of Australian manufacturing casualties, forced out of the market by giant North American and Danish competitors with fearsome economies of scale.

That it remains a dominant force in Australia and is now looking to compete on the world stage can be largely attributed to two things – a willingness to innovate and a focus on artisanal quality.

“We’re not a linear producer, we don’t employ production lines in the conventional sense,” explains John. “We don’t just put our products on a conveyor belt and use an automated system to monitor them. We have a little bit more emphasis on human intervention. Machines can’t taste, touch, feel and smell, and people can.”

Despite moving a massive volume of product – the company sold seven million hams in the lead-up to last Christmas – Bertocchi Smallgoods has resisted the temptation to sacrifice quality for quantity.

“Our hams are still handcrafted using the traditional methods, combined with the four decades of processing knowledge that’s now been built up,” notes John. “They’re made from full-muscle pork that’s baked and smoked with a selection of hickory and Tasmanian ash. It’s the same with our wide variety of salamis – they are all lovingly made by hand and left to air dry naturally – we don’t use additional heat to speed up the maturation process. Plus, everything in the Bertocchi Smallgoods range is made without additives, artificial flavours, emulsifiers or fillers.”

Blending an artisanal approach with mass production seems to have paid off, with the company’s products having been showered with awards including, most recently, ‘Best Nationally Available Ham’ at the 2014 Australian Ham Awards and ‘Best Nationally Available Bacon’ at the 2014 Australian Bacon Awards.

“We’ve got a laboratory on site where we carry out lots of R&D [research and development] for things such as the line of free-range bacon we recently created for Coles,” says John. “People from around the north of Melbourne stop by and try what we’re developing and let us know if a product is likely to work or not. There are two exciting opportunities we’ll be using the lab and our other infrastructure to explore in the near future. Firstly, we want to move into other food products, such as cheeses, dips and ready-to-eat meals. Secondly, we’re determined to start exporting our products, particularly to south-east Asia.”

John says it’s blending the best of new technology with time-tested techniques while remaining an Australian owned business that he finds most gratifying.

“There are not many Australian companies that can state, ‘we produce a world-class product, using world-class ingredients and still handcraft it in the traditional way’. I believe this company and it’s commitment to providing the finest quality smallgoods is something that’s sure to continue for many generations to come.”

This article was first published in Business View magazine (Winter 2015). For more articles and interactivity, download the iPad edition of Business View for free via our app, NAB Think.

More from NAB:

© National Australia Bank Limited. ABN 12 004 044 937 AFSL and Australian Credit Licence 230686.